Product description

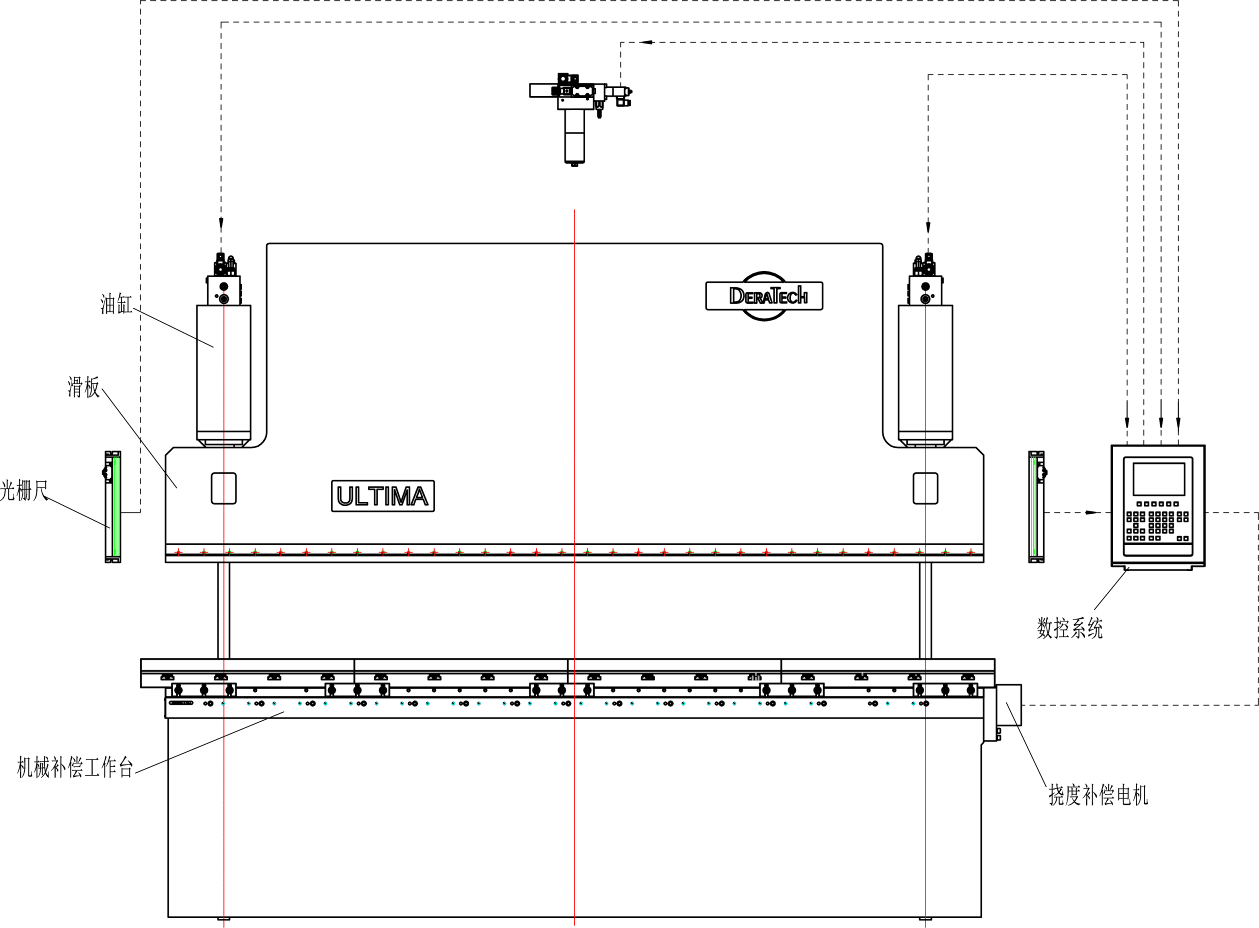

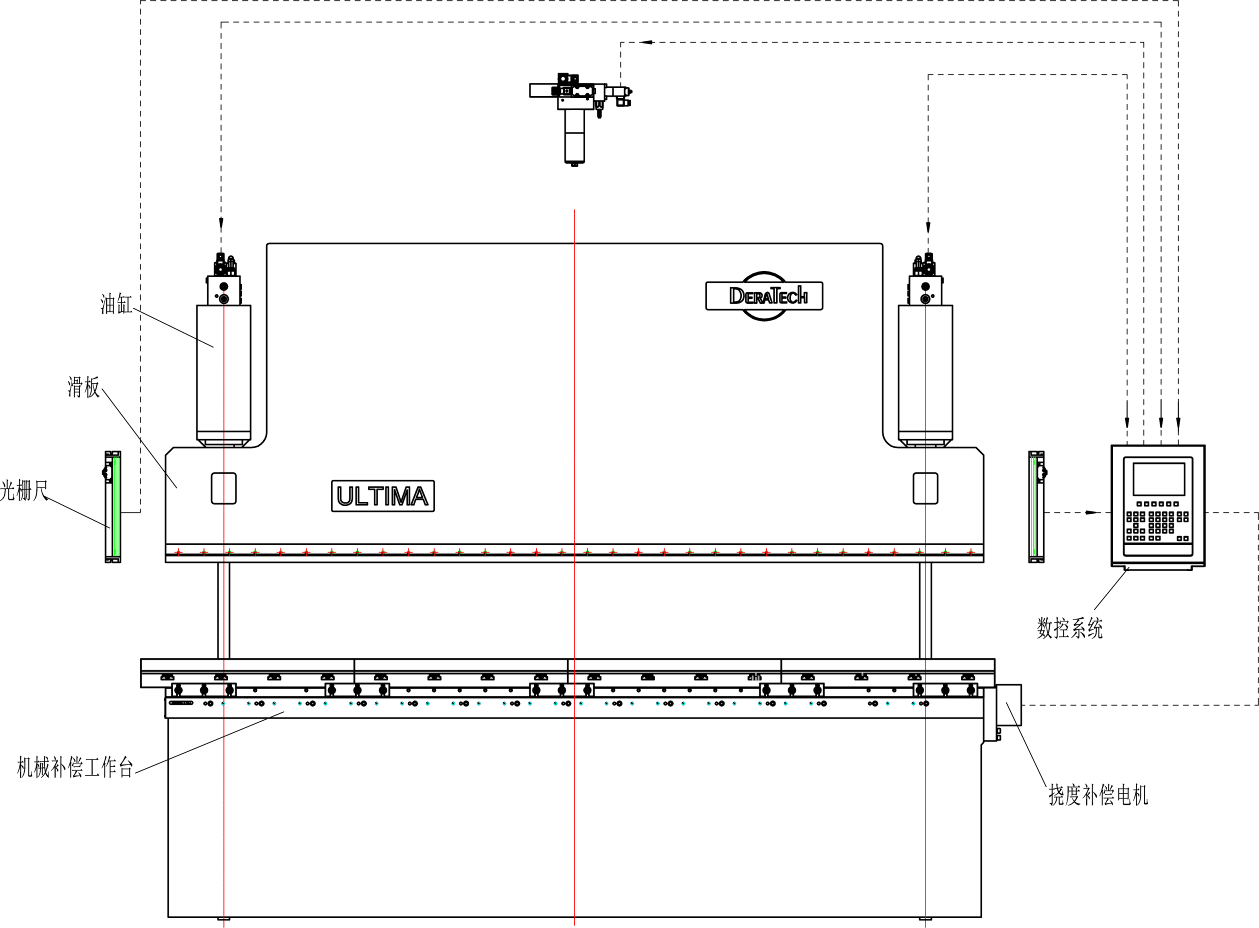

The main structure and performance of machine tools:

The machine adopts Belgian DERATECH company's latest technology design and manufacture to ensure the strength, rigidity and safety of the machine. The machine is of simple and beautiful appearance, exquisite workmanship, machining and assembly of parts. The machine adopts the overall quality steel plate welded structure, the frame is heavy and rigid, and the machine is painted with imported antirust primer and top coat to make the machine durable. The rack and upper work slider are machined by precision machine tools, such as imported large CNC Floor milling, etc., to ensure the location requirement of each mounting surface.

This machine tool is mainly composed of frame, upper slide plate, rear retaining system, slider and synchronous control device, mould, control system and so on.

(1) rack part: this part is a frame structure, which is composed of worktable vertical plate, left and right side plate, coupling beam, mechanical compensation device and so on. The steel plate is solidly welded, with good rigidity, high strength and good distortion resistance. The internal stress is eliminated by surface shot peening treatment, so as to ensure the lasting stability of the overall accuracy of the machine tool. When the bending is carried out, the upper slide plate and the worktable have small deformation to ensure that the workpiece has excellent straightness and angle consistency.

(2) upper skateboard part: The left and right cylinders are fastened by bolts with the frame. The cylinder piston rod and the slide block are connected by a spherical pad and a screw rod. The structure enables the slide block to improve the working state of the piston rod and the binding performance of the piston rod and the slide block when bearing the partial load, and the slider and the frame are connected by a rectangular guide pair with self lubrication function; the C plate on both sides of the rack is equipped with a measuring accuracy of 0.005. The grating ruler of MM is used to detect and feedback the synchronous movement state of two cylinders, so as to control the position of the slider stroke.

(3) mould and clamping device: the mould is made up of two parts, the upper die and the lower die, which are wholly quenched and durable. The upper die is installed on the slide block, and is fixed by the quick clamping plate clamping device. The lower die is in the form of concentric die, which is convenient and quick for changing die, reducing labor intensity and improving production efficiency.

(4) front support bracket: this part is a standard component, mounted on the front side of the table. When used, the bracket can be moved manually to the appropriate position according to the length of the workpiece, and the bracket can be adjusted in horizontal and vertical directions.

(5) special structure of throat deformation compensation device: each side of the machine tool is equipped with a grating ruler to measure and feedback the exact distance between the slider and the lower worktable. The grating ruler is connected with the worktable through the C frame, which eliminates the influence of the deformation of the throat of the rack on the position of the slider. When the slider is running, the position data is fed back to the numerical control system, and the output signal of the numerical control system controls the work of the proportional servo valve to control the actions of the two proportional servo valves respectively, so as to keep the two cylinders in an accurate synchronization.

This structure can make the machine have the ability of resisting partial load and effectively prevent the non-standard workpiece from interfering with the grating ruler.

(6) rear stopper device: adopt Belgian latest design accurate and stable backstop device, servo motor drive ball screw, has the characteristics of fast speed and high positioning accuracy; novel and unique double linear guide rail structure, ensure excellent positioning accuracy; multi level gear design, increase positioning range, value for money; modular design, control shaft number can be from single axis X, Matching to most axes.

(7) mechanical compensation device: when bending the sheet, the upper slide plate will inevitably produce flexural deformation, so that the bending angle of the workpiece will be small in the two ends and large in the middle. This machine tool is equipped with compensation iron and controlled by CNC numerical control system, so that the lower worktable produces flexural deformation of the upper convex compensation upper slide plate, and the angle variation of the workpiece is controlled within the tolerance range, so as to ensure the high quality bending accuracy.

(8) suspension arm system: more suitable for ergonomics suspension arm system, set a reasonable radius of rotation, more flexible and more convenient to operate.

The oil pump adopts the German VOITH Voith high performance internal gear pump, which has the advantages of high volume efficiency, small pressure fluctuation, low noise, light weight, wide viscosity range and good oil absorption characteristics.

Technical parameter

Serial number | Name | Company | Parameter value |

One | Nominal pressure | KN | Four hundred |

Two | Bending Length | Mm | One thousand and five hundred |

Three | Column spacing | Mm | One thousand and one hundred |

Four | Slider stroke | Mm | One hundred and fifty |

Five | Maximum opening height | Mm | Four hundred and thirty |

Six | throat depth | Mm | Three hundred and twenty |

Seven | Worktable height | Mm | Eight hundred |

Eight | Maximum speed of slider operation | Flooding | Mm /s | Two hundred |

Nine |

| Suppress | Mm /s | 0.2-50 |

Ten |

| Return trip | Mm /s | Two hundred |

Eleven | Main motor power | KW | Fifteen |

Twelve | Outline size (L * W * H) | Mm | 1900*1500*2300 |

Thirteen | Machine weight | KG | Three thousand and five hundred |

Machine models: YDP-PES series Y1, Y2, X, R, Z1, Z2, W (6+1 axis)

Y1Y2 axis - control slider up and down motion, X axis - control after file up and down movement

R axis - control after file up and down movement Z1Z2-- control class move around.

W axis -- workbench compensation

Main precision index:

The positioning accuracy of the slider is Y1, Y2 + 0.02 mm.

Slider repeat positioning accuracy Y1, Y2 + 0.01 mm

Angle tolerance of bending workpiece: + 30'/ full length.

Repeat positioning accuracy of rear axle X axis: less than or equal to 0.01mm

Electrical control system:

1. the electrical components mainly adopt SIEMENS brand, which is in line with international standards, safe and reliable, and has strong anti-interference ability.

2. with movable foot switch control station, it has the functions of on-off, shutdown and emergency stop, which is convenient for operation.

3. the wiring of the electric cabinet is reasonable and clear, which is convenient for maintenance or troubleshooting, and the heat dissipation effect is good.

Equipment working environment:

Power requirements: three phase four wire system, 380V, 50Hz

Installation site: clean and dusty.

Maximum temperature: 40 C

Minimum temperature: -5 C

Relative humidity: 55 - 85%

Altitude: below 1000M

Measurement standards for machine noise:

A weighted sound pressure level LPA = 82dB (A)

A weighted sound power level LWA is less than 94 dB (A).

Standards for machine execution:

JB/T 2257.1-1992 "technical specification for plate bending machine"

JB/T 2257.2-1999 "plate bending machine type and basic parameters"

GB/T 14349-2011 "precision bending machine for sheet metal"

GB 24388-2009 "noise limit of bending machinery"

The characteristics and functions of the special CNC system:

1. characteristics

All metal shell, the latest fashion modeling.

Advanced embedded CPU hardware technology

Intelligent cruise, dynamic operation prompt

Two dimensional graphics programming, workpiece side view graphics real-time tracking display

Single page programming

Two dimensional simulation of bending process, and hints of feeding direction in every step during processing.

2. scope of application

Electro hydraulic synchronous bending machine with graphic display

All requirements for high-grade electro-hydraulic servo synchronous bending machine

3. automatic calculation function

Automatic calculation of bending process

Automatic correction function

Icon toolbar simulation bending

4. main performance

High quality big keyboard operation panel, can wear gloves operation

High brightness and resolution 7 "TFT true color LCD display

Chinese operation interface

Standard 6 axis control

Shortcut theme key, pop-up menu

Drop down product graphics library and mold library

Integrated machine tool operation panel

Stainless steel handle

Brand configuration of key components:

1. oil pump VOITH company (Sino foreign joint venture)

2. numerical control system (special control system)

3. grating ruler RSF company (Austria)

4. actuator and servo motor (Japan, Sichuan)

5. circuit breaker group SCHNEIDER (Germany)

6. relay group SCHNEIDER (Germany)

Security training, on-site training and acceptance:

1. the buyer needs to prepare the required cable and power supply and prepare the foundation in advance as required. When the standby bed is delivered to the buyer's site, the buyer is responsible for providing the spreader and the general tool to make the machine tool drop. The seller is responsible for the relevant assistance.

2. when the machine tool arrives at the site, the seller immediately sends the personnel to the buyer's site to install and debug, and to train and manage the buyer's operation and management personnel, so as to ensure that the buyer's operator can operate and maintain independently and skillfully.

3. acceptance criteria for machine tools: according to relevant national standards and acceptance terms agreed by buyers and sellers, confirm that machine performance and other technical specifications are in conformity with the contract stipulations.

Quality assurance and after sales service:

1. the goods under the seller's guarantee contract are completely new and qualified products.

2. the quality guarantee period is 12 months from the date of acceptance of the equipment. During the quality guarantee period, the seller is responsible for repairing and replacing the unqualified parts due to the seller's quality problems. The buyer is responsible for the replacement of the parts cost due to the quality problems caused by the buyer.

3. our company provides direct technical support and services to users, providing users with fast and high quality services. Respond within 4 hours after receiving the call (or fax) provided by the user, and send the service personnel to the equipment within 24 hours.

4. as a machine tool manufacturer, our company has a full set of sufficient spare parts, vulnerable parts and spare parts inventory, which can provide users with reliable and fast supply of spare parts.

If there are unclear questions / questions, please contact us in time. We will serve you wholeheartedly.